The wiring harness is the main network of automotive and motorcycle circuits, the "central nervous system" of automobiles and motorcycles, an important component connecting power supplies and various electrical components, and a carrier for transmitting various signals. The wiring harness of the entire vehicle must meet technical requirements such as high and low temperature resistance, salt spray resistance, vibration resistance, and waterproofing. Meet the needs of complex conditions and environments during driving. Due to the unique nature of the automotive and motorcycle wiring harness industry, the TS16949 system will be used to control the manufacturing process.

The copper wire used for the wiring harness of automobiles and motorcycles is made of copper multi-core flexible wires, with several to dozens of soft copper wires wrapped in plastic insulated pipes (polyvinyl chloride), which are soft and not easy to break. The commonly used specifications have a cross-sectional area of 0.5-12 square millimeters, and each allows for load current values. Wires with different power consumption devices are used. The material selection is very strict, and its electrical performance, emissivity, temperature resistance, flame retardancy, waterproofing, and other safety requirements are even more stringent.

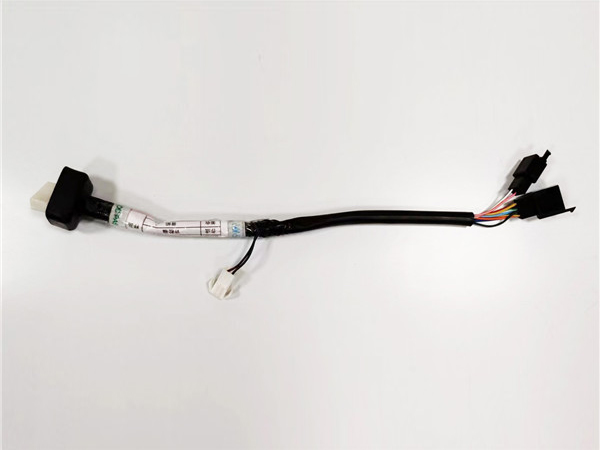

After the production process wiring diagram is produced, it is first decomposed into a production process diagram. Based on the drawings, various wire colors are decomposed into the required lengths, and a wire cutting and wiring table is made, which is then sent to the production department. According to the cutting and connecting table and samples, the production department starts from cutting, wiring, crimping, grouping, wiring, bundling, testing, inspection, packaging, and warehousing.